Excel Laboratories Coimbatore

Manufacturers of Polypropylene Filters. Mobile: 09843019701 Email: info@excellaboratories.com

Monday, July 14, 2025

Polypropylene Tanks Manufactured by Excel Laboratories Coimbatore

Thursday, July 10, 2025

Thank You for visiting our stall at ISF 2026

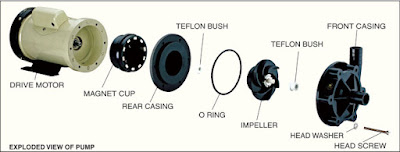

Excel Laboratories, based in Coimbatore, is a leading manufacturer specializing in high-quality filtration solutions and magnetic pumps.

The company produces a range of products, including disk-type filters, bag filters, and cartridge filters, designed to meet diverse industrial filtration needs. These filters are crafted for efficiency, durability, and precision, catering to applications in water treatment, chemical processing, and more. Excel Laboratories is also renowned for its innovative magnetic pumps, which offer reliable, leak-free performance for handling corrosive and hazardous fluids. With a commitment to quality and customer satisfaction, Excel Laboratories leverages advanced manufacturing techniques and stringent quality control to deliver products that meet industry standards.

For inquiries, contact them at info@excellaboratories.com or +91- 9843019701

Sunday, October 13, 2024

Polypropylene Filter bags

Bag filters are used for the clarification/filtration of fluids that have a relatively small loading of particles to be removed. The particle suspension passes through and the particles settle in the bag. Filtration occurs from inside to outside with a delivery speed of about 100 m3/m2 h.

Saturday, October 12, 2024

Magnetic Drive Pumps

Friday, October 11, 2024

Thursday, August 15, 2024

Polymeric Flocculating Agents - POLYELECTROLYTE

#polyelctrolytes To buy email us at info@excellaboratories.com pic.twitter.com/co4oeY3DpL

— Excel Laboratories (@excellabindia) August 15, 2024

| ||||||||||||||||||||||||||||||

|